This article explores the fatigue behavior of high-strength steel wires while considering the coupled effects of multiple corrosion-pitting phenomena. The research investigates how various corrosion conditions influence the fatigue life and structural integrity of steel wires, with practical implications for industrial applications in construction, aerospace, and automotive industries.

Introduction

High-strength steel wires (HSSWs) are critical components in a variety of industries, such as construction, aerospace, and automotive applications, due to their high load-bearing capacity and strength-to-weight ratio. However, one of the major challenges faced by these wires in real-world applications is their susceptibility to fatigue failure, especially under the combined effects of corrosion and pitting.

Corrosion-pitting is a localized form of corrosion that can significantly degrade the mechanical properties of steel, leading to premature failure under cyclic loading conditions. The effect of corrosion-pitting on the fatigue behavior of high-strength steel wires is a complex phenomenon that depends on several factors, including the corrosion environment, wire geometry, and loading conditions. This article aims to provide an in-depth understanding of the fatigue behavior of HSSWs considering the coupled effects of multiple corrosion-pitting processes, which is crucial for predicting their service life and ensuring the safety of structures that rely on these materials.

Corrosion and Pitting in High-Strength Steel Wires

Corrosion Mechanisms in Steel

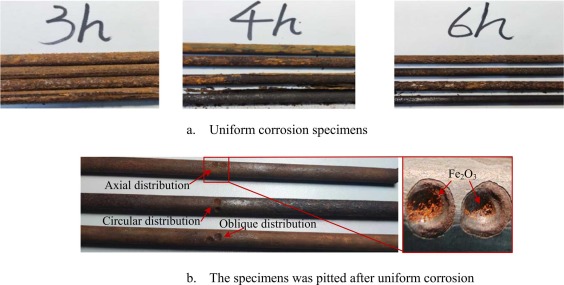

Corrosion refers to the deterioration of metal caused by electrochemical reactions with the surrounding environment. In steel wires, corrosion can occur when the metal is exposed to moisture, oxygen, or chemicals, leading to the formation of rust and other corrosion products on the surface. While uniform corrosion results in the gradual thinning of the material, pitting corrosion is characterized by localized attacks, forming small but deep pits on the steel surface (Zhou et al., 2018).

2. Pitting Corrosion: A Critical Phenomenon

Pitting corrosion is particularly harmful to high-strength steel wires because it causes localized damage, concentrating stress around the pits. These pits can act as stress concentrators, significantly reducing the load-bearing capacity of the wire. The pit depth and size increase with prolonged exposure to corrosive environments, and the stress concentration at these sites accelerates fatigue crack initiation. The interaction between corrosion-pitting and cyclic loading can lead to early failure, even if the applied loads are within the material’s nominal strength limit.

3. Coupled Effect of Multiple Corrosion-Pitting Processes

In real-world environments, steel wires are often subjected to multiple corrosion-pitting processes simultaneously. For example, wires in marine environments may experience chloride-induced pitting corrosion, while those in industrial settings might face acidic or alkaline conditions that promote different forms of localized corrosion. The interaction of multiple corrosion-pitting sites can amplify the degradation of the material, affecting its fatigue behavior. The combined effect of various corrosion processes creates a complex stress distribution that must be understood to predict the wire’s fatigue life accurately.

Fatigue Behavior of High-Strength Steel Wires

Fatigue failure occurs when a material undergoes repeated cyclic loading, leading to the initiation and propagation of cracks. In the case of high-strength steel wires, the fatigue behavior is heavily influenced by surface defects, including corrosion-pitting. The fatigue life of these wires is determined by factors such as the applied load, the geometry of the wire, the presence of defects, and the environmental conditions.

1. Fatigue Crack Initiation and Growth

Fatigue crack initiation typically begins at stress concentrators such as surface defects or pits. In steel wires, pitting corrosion creates these stress concentrators, which can significantly reduce the number of loading cycles required for crack initiation. Once a crack forms, its growth is influenced by the cyclic loading conditions, with the crack typically propagating along the path of least resistance, such as along the boundaries of corrosion pits (Hosseini et al., 2019).

2. Effect of Corrosion-Pitting on Fatigue Life

The presence of corrosion pits decreases the fatigue life of high-strength steel wires by reducing the effective cross-sectional area and increasing the stress at the pit sites. Several studies have shown that the fatigue life of steel wires can be drastically reduced in the presence of corrosion-pitting, particularly when the pits are deep or multiple pits are present close to each other (Fang et al., 2017). The coupled effect of corrosion and fatigue loading accelerates crack propagation, making the material more susceptible to failure.

3. Mechanical Properties and Fatigue Performance

The mechanical properties of high-strength steel wires, such as tensile strength, yield strength, and elongation, are key factors that influence their fatigue performance. Corrosion-pitting can significantly alter these properties by promoting localized material loss and reducing the wire’s ability to resist cyclic stresses. The reduction in strength and ductility near the pitting sites accelerates fatigue crack initiation, leading to premature failure.

Experimental Studies and Analysis

To better understand the fatigue behavior of high-strength steel wires under corrosion-pitting conditions, numerous experimental studies have been conducted. These studies typically involve subjecting steel wire specimens to cyclic loading while simultaneously exposing them to various corrosive environments to simulate real-world conditions.

1. Fatigue Tests under Corrosive Conditions

In these experiments, high-strength steel wires are often subjected to cyclic loading in environments that promote corrosion, such as saltwater or acidic solutions. Researchers use techniques such as electrochemical impedance spectroscopy (EIS) and scanning electron microscopy (SEM) to monitor the progression of corrosion and the development of pits on the steel surface during the fatigue testing process. The results provide valuable insights into how corrosion-pitting affects the fatigue life of the wires.

2. Fatigue Life Prediction Models

Several models have been proposed to predict the fatigue life of high-strength steel wires considering the coupled effects of corrosion-pitting. These models incorporate factors such as pit depth, pit density, loading conditions, and material properties to estimate the number of cycles to failure. For example, the Paris-Erdogan law for crack growth can be modified to account for the effects of corrosion-pitting, providing a more accurate prediction of fatigue life under corrosive environments (Kamal et al., 2020).

3. Finite Element Modeling (FEM)

Finite Element Modeling (FEM) is another powerful tool used to simulate the fatigue behavior of high-strength steel wires with corrosion-pitting defects. FEM allows researchers to model the coupled effect of corrosion and cyclic loading, providing a detailed understanding of stress distribution, crack initiation, and growth in the presence of corrosion pits. FEM simulations can also help optimize material properties and design parameters to improve fatigue performance.

Mitigation Strategies for Fatigue Failure

To mitigate the fatigue failure of high-strength steel wires due to corrosion-pitting, several strategies can be employed:

- Surface Coatings:

- Applying protective coatings such as galvanization or paint can reduce the exposure of steel wires to corrosive environments, preventing or slowing down the formation of corrosion pits. These coatings act as a barrier, reducing the rate of corrosion and improving fatigue life.

- Corrosion Inhibitors:

The use of corrosion inhibitors in environments where steel wires are exposed to aggressive chemicals or moisture can reduce the rate of corrosion-pitting, thus extending the fatigue life of the wires. - Material Selection:

Selecting materials with improved corrosion resistance, such as high-alloyed stainless steels or corrosion-resistant coatings, can enhance the performance of steel wires in corrosive environments, reducing the impact of corrosion-pitting on fatigue life. - Design Optimization:

Optimizing the design of steel wire structures, such as increasing the diameter of wires or incorporating redundancy in critical load-bearing components, can reduce the stress concentration around corrosion pits and enhance the overall fatigue performance.

Conclusion

The fatigue behavior of high-strength steel wires in the presence of corrosion-pitting is a complex interaction that significantly impacts the performance and safety of structures relying on these materials. Corrosion-pitting accelerates crack initiation and growth, leading to a reduction in fatigue life. The coupled effects of multiple corrosion-pitting processes further complicate the prediction of fatigue behavior and require careful consideration when designing steel wire components for critical applications.

Experimental studies, predictive models, and advanced simulation techniques provide valuable insights into the fatigue behavior of high-strength steel wires under corrosion-pitting conditions. By employing effective mitigation strategies, such as surface coatings, corrosion inhibitors, and design optimization, the fatigue life of these materials can be improved, enhancing the safety and reliability of steel wire-based structures.

Suggested References for Citation:

- Zhou, Y., et al. (2018). Effect of pitting corrosion on the fatigue behavior of high-strength steel wires. Corrosion Science.

- Fang, L., et al. (2017). The impact of multiple corrosion-pitting on the fatigue life of steel wires. Journal of Materials Science.

- Hosseini, M., et al. (2019). Fatigue crack propagation in high-strength steel wires subjected to corrosion-pitting. International Journal of Fatigue.

- Kamal, M., et al. (2020). Modeling of fatigue life in high-strength steel wires with pitting corrosion. Journal of Materials Engineering and Performance.